The project proposes the dimensioning of the cold store in its aspect of cold production and complementary services.

After the sizing of the facilities, the respective insulation is defined and the thermal balance is calculated from which the cold stores will be dimensioned.

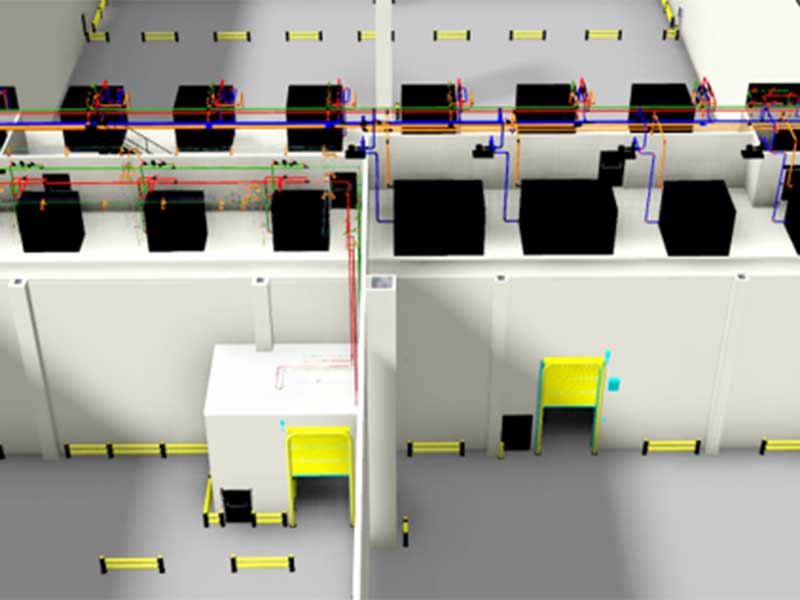

The “layout” of the installation, usually prepared by the customer, is optimized by us with the necessary specific corrections of the specialty, after which we select the most appropriate cooling system, taking into account in particular the minimization of the initial costs and the energy expenditure .

In addition to the usual facilities, we design environmentally friendly “green” refrigeration plants using both ammonia and carbon dioxide as refrigerants.

Textile Pipes – For a quiet distribution of low air velocity along the spaces that surround them, also ensuring a high level of hygiene.

We design and carry out the inspection of the respective assemblies of industrial refrigeration installations, namely for the preservation of fresh and frozen products, ice-making facilities, continuous and discontinuous freezing tunnels, slaughterhouses, cold stores, etc.

Evaporators – They have the function of removing the heat from the surrounding environment and therefore generating the “Cold Production”

Evaporative Condenser – Units that combine the air with a cooling tower and that has the particularity of effecting the conservation of water.

This type of condenser has mechanical ventilation and the air stream passes through a set of tubes where the refrigerant flows.